Processing Asparagus without Any Breakage or Bending

The green asparagus has undoubtedly marked its presence in the global market in the past years. Another two members of the asparagus family, the white and purple varieties, even though they haven’t gained as much exposure in North America, are having well-deserved popularity in Europe and western Asia. The demands are only increasing. As a high-value vegetable, whether fresh or frozen, any slight damage to its spear or tip would lower the selling price. Especially peeled white asparagus, they are more delicate and difficult to process. All thin and long asparagus easily get tangled together during processing. Breakage and tangling often happen when asparagus are transferred between belts. Another issue is that it is desired to have products come out in good order for easy packing, preferably as it has been loaded on the first belt.

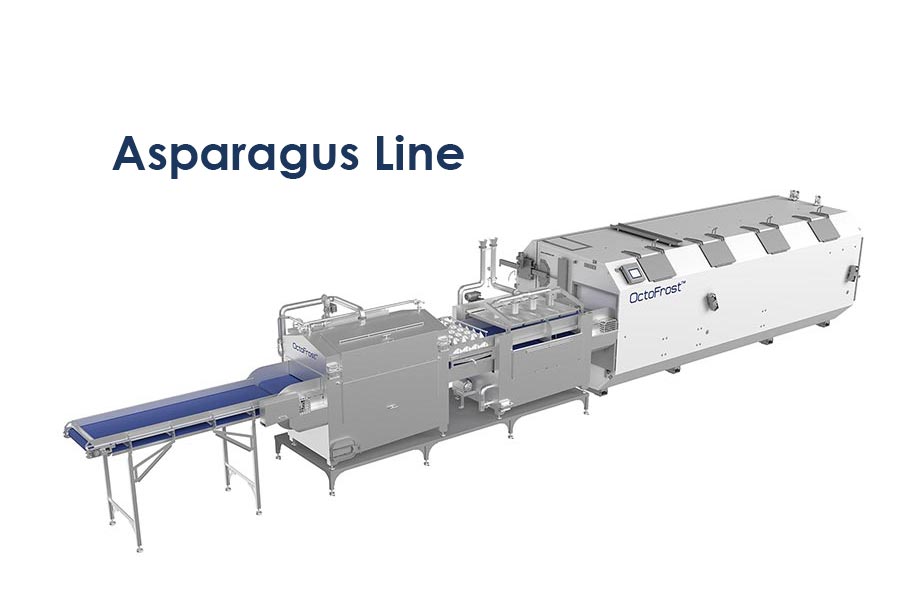

OctoFrost has already put an asparagus line on the market that solves the issues of processing asparagus.

Horizontal processing line for asparagus of any color with no manual handling required

The OctoFrost™ whole asparagus processing line consists of the IF blancher, IF chiller, and IQF tunnel freezer. It is one horizontal line, which means asparagus lays statically during the entire processing time and comes out of the Freezer how it is put on the blancher belt. Therefore, no additional manpower needed, which is more hygienic. And there will be no damage to the tips of asparagus since no drop of products during the process.

Traditional asparagus lines offer multiple belt solutions in different levels that not only result in broken tips of asparagus but also unsorted products, which requires extra workforce to sort at outfeed of IQF freezer.

Pre-treatments before going into the Freezer

It is recommended to pre-cool fresh asparagus in a hydro cooler at +1C before Freezer. The reasons are higher capacity, lower total processing cost, and better bite and color.

Best practice in Blancher and Chiller

Before entering the Blancher, asparagus manually shall be loaded lengthwise and can be with a rather high bed depth to achieve capacity; This requires an efficient penetration of blanching water at high volumes to reach a uniform blanching and chilling.

Best practice in Freezer

Unlike other vegetables, the air circulating inside the IQF Freezer needs to be set in a way that the product is not moving at all when freezing. In the Freezer, forced and controlled airflow is fast and efficient without creating “rat holes” that make products disordered.