THE EVOLUTION OF IQF TECHNOLOGY

IQF stands for Individual Quick Freezing and is a technology used in the food processing industry. As the term suggests, it stands for the quick freezing of individual pieces of product, as opposed to bulk or block freezing.

IQF technology has its roots back in the 1960s when the freezing tray freezer was introduced on the market. It was an immediate success as the prior freezing methods were block freezing of products (or even packaged products) which degraded the overall quality due to its long freezing time. Tray freezer performed well on “easy to freeze” products like pea, corn or carrots. The transportation of the product was based on the fluidization principle. However, for rather delicate and light weight products like broccoli, raspberries, herbs, etc. the air speed needed to achieve transportation was too high and products would get destroyed or flown over the bed.

Therefore the flexibility of this type of freezer was limited.

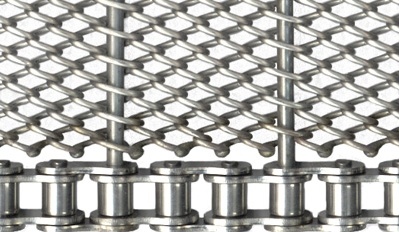

In 1970s the engineers came up with a solution and introduced the transportation belt. With this innovation it was possible to transport the product at lower air speeds, as the belt was in charge of transporting the product. However, by introducing a belt in the freezer the number of moving parts increased which is a hazard for food safety. In addition, a belt-take-up mechanism was necessary to be introduced due to temperature variations. Since 1970s, stainless steel type of mesh-belt was used in IQF freezers. Many freezers today use the same type of technique even if belt configuration can vary. The disadvantage of this belt is that it cannot produce true fluidization, as the holes in the mesh are too big. In addition, such belts would always leave belt marks on relatively fragile products such as strawberries. An efficient cleaning of such type of belt is difficult which is another important drawback.

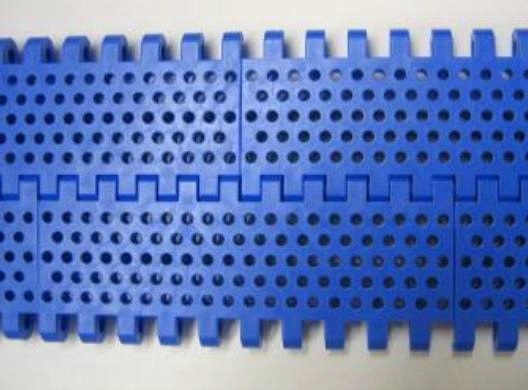

As a response to these challenges, in 1980s plastic belts were introduced in the IQF freezers, a technology which significantly improved the freezing results. The challenge for this type of belts is that only 64% of the surface of the belt has active fluidization while the rest of 36% is a dead zone as the air flow is hindered by the connection pins.

The latest innovation in terms of beds used for IQF freezers is the perforated bed plate designed by OctoFrost company which is a successful replacement for the belts used before. Transportation of the product is based on a patented principal which consists of an asymmetric movement of the bedplate in the direction of transportation using static friction between the bedplate and the product to be frozen. In the case of the OctoFrost IQF freezer bed plate – almost 100% of the surface of the bed has active fluidization. The possibility of configuring the diameter and shape of the perforated holes contributes to the impressive freezing results while the cleaning of the beds can be made easy and fast outside the IQF freezer. The OctoFrost™ bedplates have marked an impressive technological progress in the IQF industry.