Home

Передовые решения для обработки пищевых продуктов Мясо и птица

Общие проблемы при IQF замораживании мяса и птицы

Замораживание высококачественных продуктов из мяса и птицы требует аккуратного обращения и соблюдения мер пищевой безопасности, чтобы избежать распространенных проблем, таких как:- Образование комков: Липкие маринованные или приготовленные продукты могут слипаться, снижая качество.

- Повреждение внешнего вида: Мясные продукты подвержены появлению хрупких краев или подгоранию в морозильной камере, что негативно сказывается на их визуальной привлекательности.

- Безопасность и гигиена пищевых продуктов: Высокие стандарты необходимы для предотвращения перекрестного заражения и обеспечения безопасности продуктов .

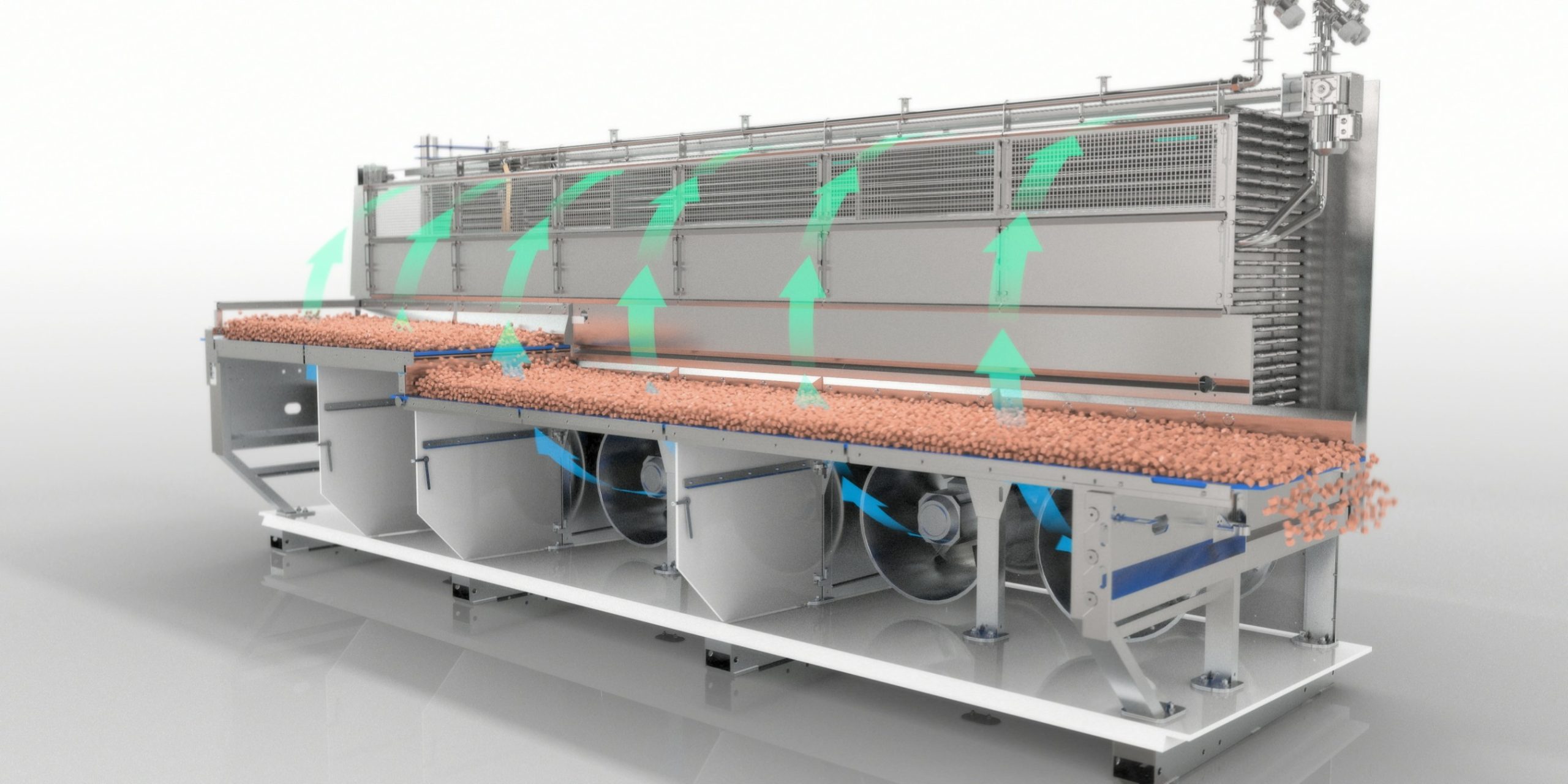

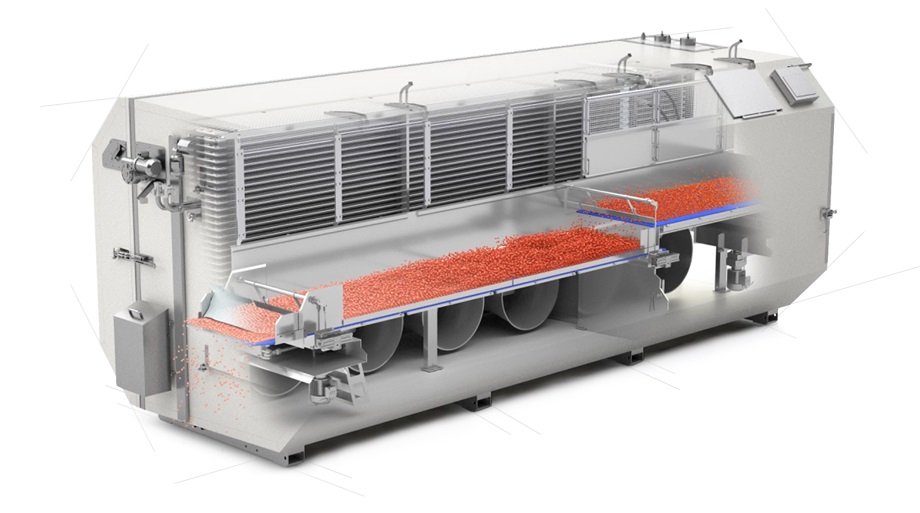

OctoFrost Solution - морозильная камера IQF

Морозильная камера OctoFrost IQF отвечает этим задачам благодаря передовой технологии, специально разработанной для мяса и птицы. Ключевые особенности включают:- Технология флюидизации: Обеспечивает хорошее разделение продуктов, предотвращая комкование и сохраняя внешний вид .

- Регулируемые зоны замораживания: Индивидуальные настройки воздушного потока минимизируют обезвоживание и обеспечивают равномерное замораживание .

- Высокие стандарты безопасности пищевых продуктов: Легко очищаемая конструкция со съемными подставками устраняет риск перекрестного загрязнения.

- Энергоэффективность: Вентиляторы с частотным регулированием снижают потребление энергии до 30%, сохраняя при этом эффективность замораживания .

Общие проблемы при импрессионном замораживании мяса и птицы

Импрегнированное замораживание продуктов из мяса и птицы ставит перед Вами уникальные задачи, включая сохранение качества продукции, оптимизацию энергоэффективности и минимизацию эксплуатационных расходов при обеспечении стабильной и быстрой заморозки .- Достижение консистенции: Тонкие или плоские продукты, такие как гамбургеры, бекон или куриные полоски, требуют равномерного замораживания , чтобы сохранить их текстуру и внешний вид.

- Минимизация обезвоживания: Длительное замораживание может привести к обезвоживанию продукта, снижению выхода и ухудшению качества.

- Гигиена и чистота: Соблюдение строгих стандартов безопасности пищевых продуктов имеет решающее значение для переработки мяса и птицы, особенно в компактных морозильных системах.

- Ограниченность пространства на предприятиях: Многие перерабатывающие предприятия сталкиваются с ограничениями по площади помещений, в то время как на требуются высокопроизводительные решения.

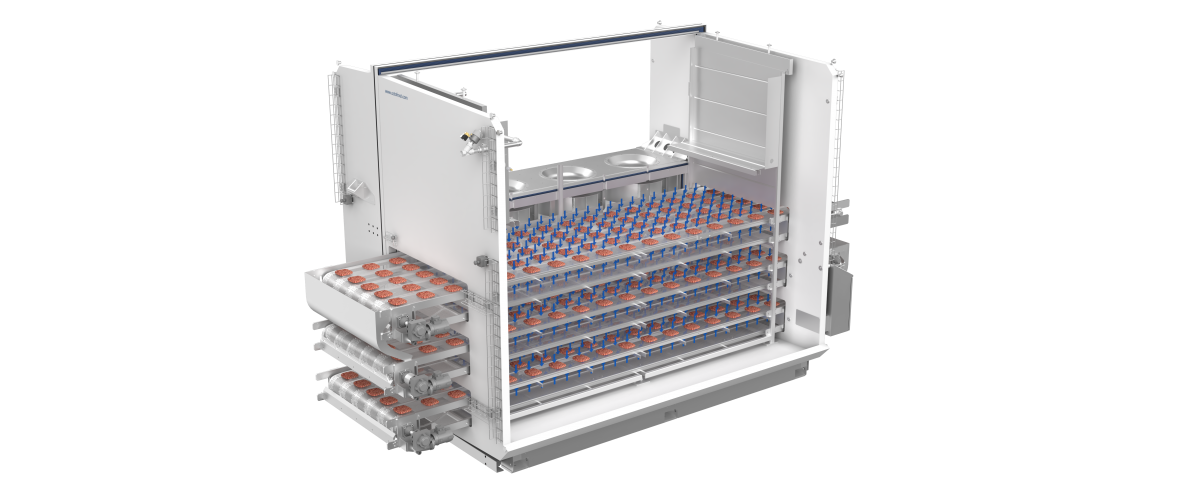

OctoFrost Solution - Импрессионный морозильник

Импрегнированный морозильник OctoFrost предлагает инновационный подход к решению уникальных проблем, связанных с замораживанием продуктов из мяса и птицы. Благодаря высокоскоростным воздушным потокам, направленным как на верхнюю, так и на нижнюю часть продукта, эта модель обеспечивает быстрое и эффективное замораживание плоских и тонких продуктов. Ключевые особенности:- Быстрое и равномерное замораживание: Использует высокоскоростное нагнетание воздуха для замораживания корочки и статического замораживания продуктов. Идеально подходит для продуктов толщиной до 25 мм, таких как гамбургеры, бекон и порционные куски курицы.

- Низкое обезвоживание: Процесс быстрого замораживания сводит к минимуму потерю влаги, сохраняя выход продукта и его качество.

- Компактный дизайн: Доступны одно- и многоуровневые конфигурации для максимального увеличения производства на квадратный метр, предлагая высокопроизводительное решение для предприятий с ограниченным пространством.

- Высокая универсальность: Подходит для различных применений, включая замораживание корочки мяса , котлет, бекона и курицы.

- Безопасность и гигиена пищевых продуктов: Открытая и доступная конструкция упрощает чистку и обеспечивает соответствие строгим гигиеническим стандартам.

Видео

Узнайте, как ведущие производители по всему миру используют технологию OctoFrost для замораживания мяса и птицы. Узнайте, как наше оборудование обеспечивает высочайшее качество и эффективность на каждом этапе процесса. Просмотрите наш плейлист на YouTube прямо сейчас.

Наш канал на YoutubeОборудование OctoFrost для мяса и птицы

ТЕСТИМОНИАЛЫ

НЕ ВЕРЬТЕ НАМ НА СЛОВО

Вот что говорят наши клиенты

СВЯЗАТЬСЯ С НАМИ